Welding Machine for miniature products

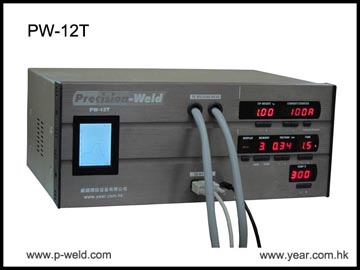

PW-12T Temperature Control Pulse Heat Unit

(Click to enlarge)

PW-12T is a high frequency inverter welder. It controlled by multi-processor and power IGBT,

which makes it possible to exercise precise control over applied voltage, pressure, current and reflow temperature during each operation.

PW-12T greatly reduce the training period of workers from weeks to just few hours. On the environmental side, no chemical solvent and insulation removal is needed, which also saves costs and labour. The device enjoys low voltage (<2.5V) operations and low energy consumption.

Specialties:

Spot Welding mode:

PW-12T is a compact size lead free device capable of handling the welding needs of very fine wires ranging 0.02mm-1.0mm.

The product utilizes the principle of high temperature welding. Current flowing through the welding tip creates a high temperature to burn off the wire insulation, and then continues through the exposed wire and the metal base to weld the two together.

Welding quality is assured by closed-loop control for welding voltage and current.

Pulsed Heat Soldering mode:

PW-12T embedded temperture control module, it operate as a Hot Bar Reflow soldering machine.

Large current flowing through the high resistance material such as Mo or W etc. and generate heat.The heat was controlled by feed back of thermocouple on the heater tip accoring to the preset temperature and time.

Soldering quality is assured by closed-loop control for welding voltage and temperature.

Suitable for . . .

- Replacement for soldering, especially suitable for miniature component, flexible circuits, ribbon cables, flex to PCB...

- Welding (Soldering) with enameled wires. No need for wire stripping.

- Printed circuit board (PCB) repairs.

- Welding (Soldering) assortment of electronic components and surface-mounted components.

- Jobs requiring thin soldering layer.

Unique Features:

1. Electronic pressure sensing technology offers higher precision than comparable products with

mechanical pressure sensing technology.

2. Quality of ordinary soldering or even welding jobs can only be visually estimated by tensile strengths. Our unique current and temperature sensing and alert system ensures quality of each welded joint.

3. Specially designed micro-controller unit (MCU) with 9 programmable weld schedules with sequential function.

4. Independent welding current and voltage detect system.

5. Key lock system setting prevents accidental changes, ensuring product quality.

6. Single or Dual welding pulse output for different products.

7. Presettable discharge counter and alert system.

Specifications:

Power Input 220V

Welding Voltage 0.2 ~ 2.0V

Welding Current 10 ~ 1200A

Duty Cycle 10%

Welding Time 5mS ~ 9.9Sec.

Welding temperature 100 ~ 600 C

![]() PW-12

PW-12

Inverter Resistance

Welder

![]() PW-12T

PW-12T

Temperature Control

Pulse Heat Unit

![]() PH Series Weld Head

PH Series Weld Head

Year 2000 (HK) Ltd.

HK Address:

Unit A., 33/F., Legend

Tower, 7 Shing Yip St.,

Kwun Tong,

Hong Kong.

Tel:

(852) 2191 8803

Fax:

(852) 2172 7276

E-mail:

welcome@year.com.hk

Website:

www.year.com.hk

China:

Dongguan Wei Shun

welding equipment Co, Ltd

Address:

4/Floor, Building B, Zhongding

Communication Industrial Zone ,Jinxiaotang Fenggang Town, Dongguan City, China

Tel:

(86) 769-8756 8791

Fax:

(86) 769-8756 5725

Mobile:

(86) 13926816048

E-mail:

year-cn@vip.163.com xjhyear@126.com

Website:

www.p-weld.com